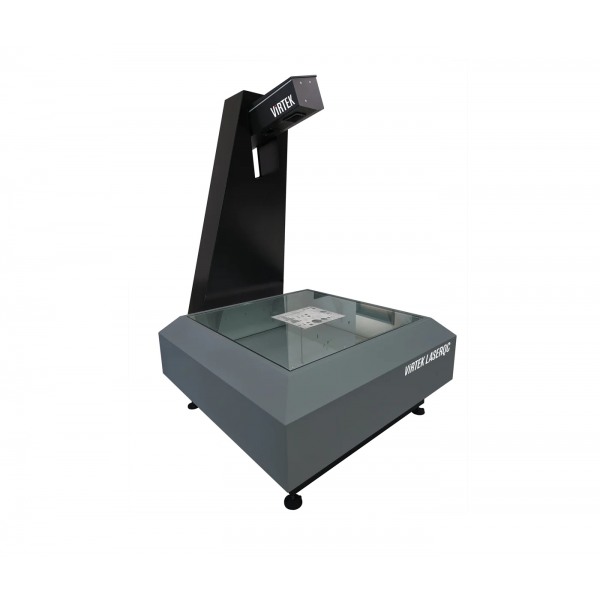

Virtek LaserQC

NEW! Virtek LaserQC® with Vision Quality System is a fast inspection system that uses lasers to measure the accuracy of two-dimensional parts within 0.05 mm (0.002 inches) and three-dimensional parts within 0.25 mm (0.010 inches), respectively.

Virtek LaserQC is a laser inspection system designed to improve accuracy and efficiency in the inspection of manufacturing parts. It uses a combination of advanced hardware and software to scan and measure parts in a matter of seconds, providing precise and reliable measurements.

The system is capable of improving quality and reducing the time and costs associated with parts inspection.

Virtek LaserQC Inspection System

Virtek LaserQC with Vision Quality System is a rapid inspection system that uses lasers to measure the accuracy of two-dimensional parts with an accuracy of 0.05 mm (0.002 in.) and three-dimensional parts with an accuracy of 0.25 mm (0.010 in.), respectively.

|

|

|

|

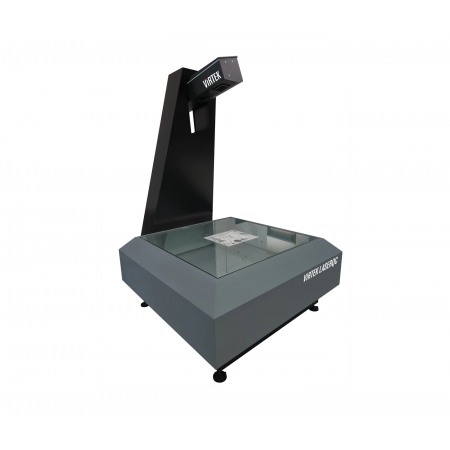

Identify Issues QuicklyVirtek LaserQC, designed for the manufacturing environment, verifies system calibration before each scan to ensure repeatable accuracy. By identifying errors immediately, waste and rework are reduced, improving profitability. |

Elevate Quality to a New LevelVirtek LaserQC captures more than 500 data points per second with an accuracy of 0.05 mm (0.002 inches). Additionally, the quality control reports instill confidence in customers. |

Start Working ImmediatelyVirtek LaserQC is designed for easy installation and can be operational within hours. The intuitive user interface allows new operators to master it fully. |

LaserQC® Delivers Results that Impact Your Business's Profitability

Fast and Simple with Laser

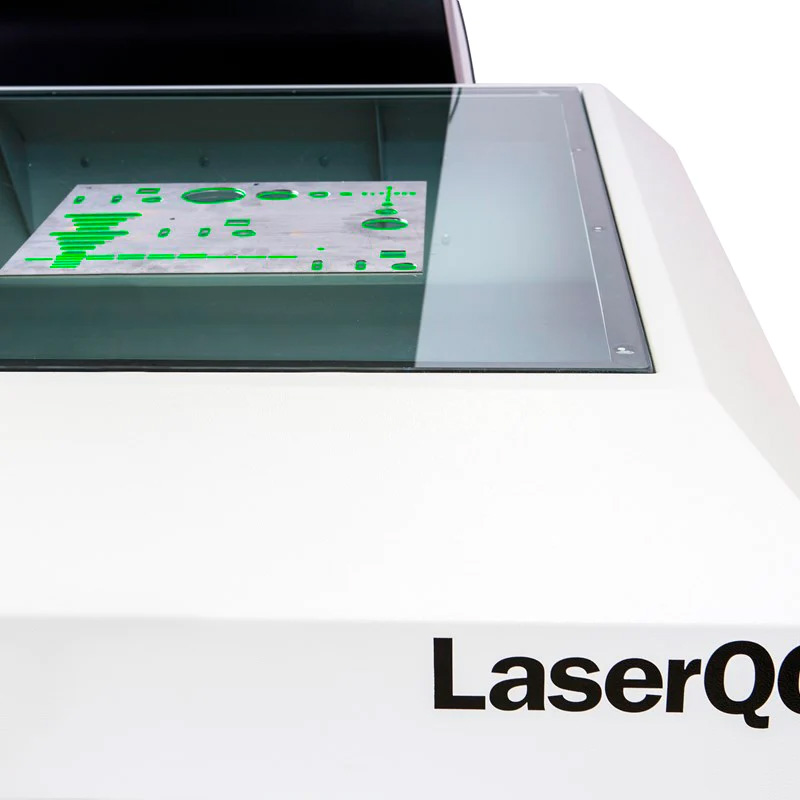

LaserQC® captures more than 500 data points per second to perform high-speed part inspections directly on the shop floor.

Designed for easy setup, so your system will be operational in less than a day.

The intuitive user interface allows new operators to become fully competent in just a few hours.

Laser Precision

The system quickly performs 100% inspections with an accuracy of ± 0.002 inches (0.05 mm) for 2D measurements and ± 0.010 inches (0.25 mm) for formed part measurements.

Shop Floor Friendly

LaserQC® offers a reliable, low-maintenance solution that operates alongside your facility's CNC equipment.

The system self-calibrates and adjusts system settings to accommodate common environmental changes in the shop.

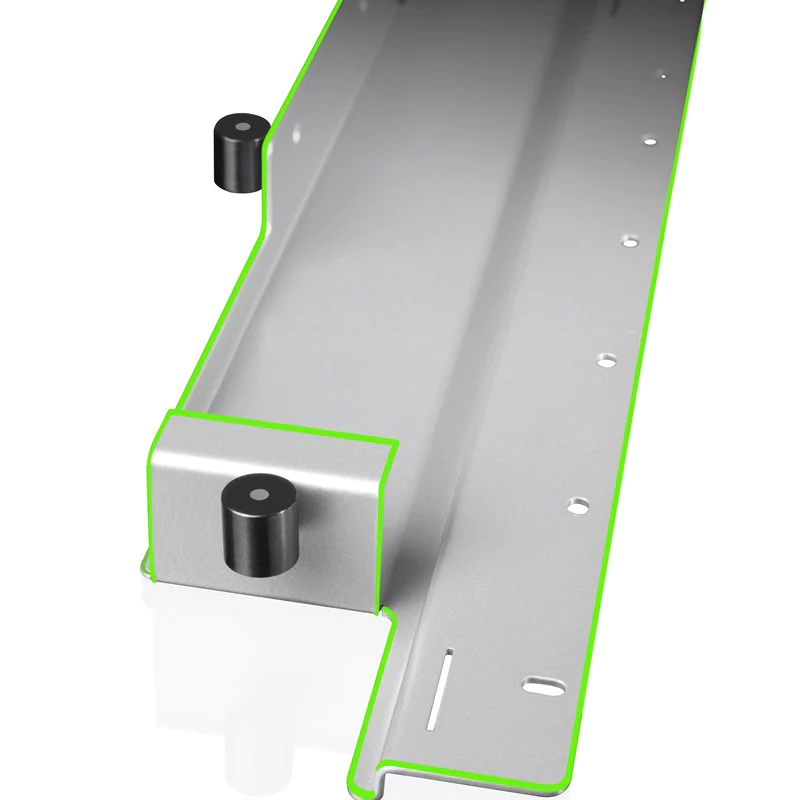

Additionally, Virtek offers a Piece Stabilizer add-on, specifically created for use in the gasket and seal industry.

| Virtek® LaserQC® is a rapid inspection system that uses lasers to measure the accuracy of two-dimensional parts with tolerances up to 0.05 mm (0.002 inches). |

You might also like