Virtek LTG

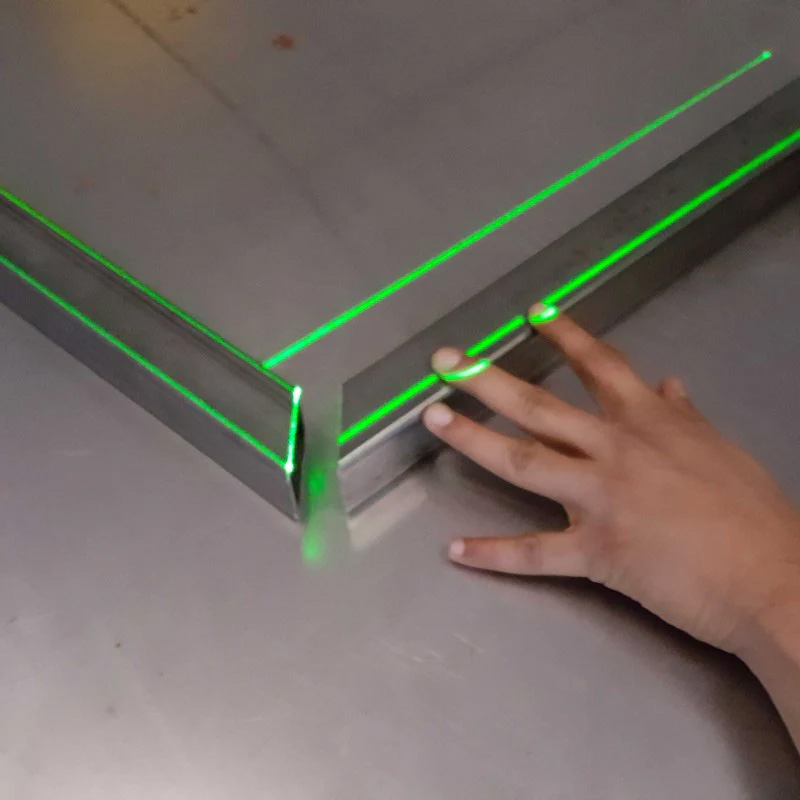

The Virtek™ Laser Template Generator (LTG) system projects a template that shows operators the exact location of all important features on each component or assembly. There is no need to consult blueprints or use a tape measure, allowing even the most complicated designs to be built in a matter of minutes.

The Virtek LTG system projects a laser outline from your CAD file to scale, showing operators the exact location of all important features in your assembly.

Virtek LTG System - Laser Template Generator

This system consists of the application of Virtek LTG software with the new Laser Projection System (LPS10) for 2D applications. Laser projection for the manufacturing of rail assemblies, wall panels, floor platforms, and steel panels.

The Virtek LTG system facilitates the design process of railings, steps, and steel structures so that even less experienced workers can be immediately productive.

The system projects a laser template from the latest CAD file to be constructed onto the work surface, highlighting the position and shape of all important parts. There is no need to consult blueprints or use a measuring tape, allowing even the most complicated designs to be built in minutes.

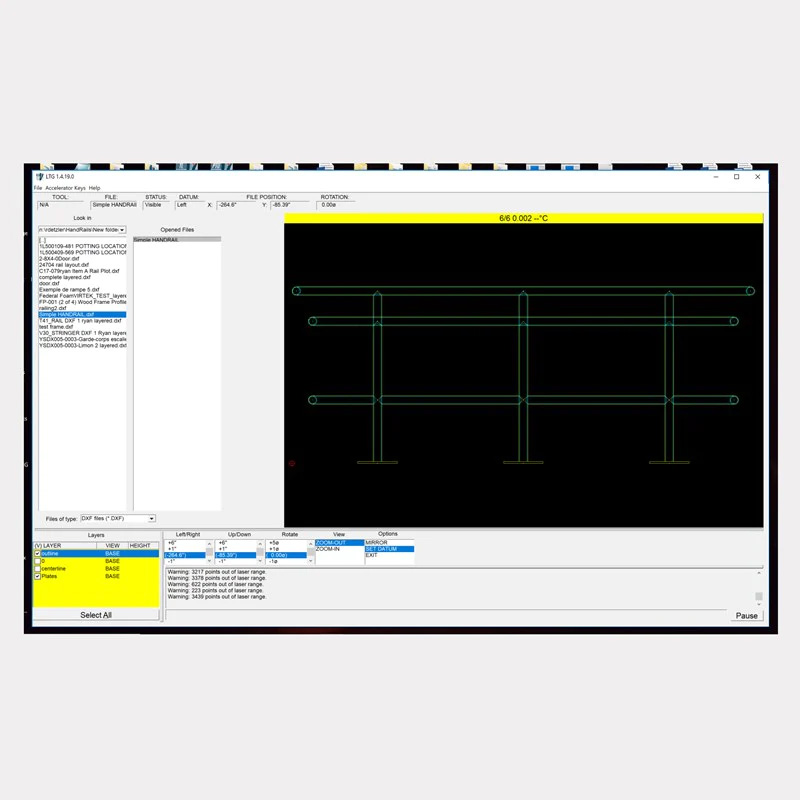

The LTG interface maximizes the investment in your existing design software. The software streamlines assembly by guiding workers through the design process.

|

|

|

Optimize PerformanceWith the Virtek LTG system, there is no need to consult blueprints or use a measuring tape, allowing wall or floor panels, even the most complicated ones, to be built quickly, reducing setup time by up to 70 percent. |

Visualize the Final ProductProject the location of studs, headers, sheathing, nailing pattern, subcomponents, openings, and inserts with a precision of ±1.6 mm (1/16 inch). Workers see how to assemble the panels before starting. The result is higher productivity and improved quality. |

Improve CommunicationInterface with leading panel design programs and AutoCAD® software. With the Virtek LTG system, engineering changes between design and manufacturing are communicated easily and efficiently. |

Increased Performance with Virtek LTG

- Reduces design and change time by up to 70%, and increases productivity by up to 25%.

- Works great for unique parts, as the image is projected instantly.

- Increases manufacturing capacity and efficiency, and reduces cost per unit.

- Training is simple and requires a less specialized workforce.

- Instantly adjust template designs or revision changes directly in the workshop.

- Designed to require very little maintenance from the customer.

| The Virtek® LTG (Laser Template Generator) system projects a laser template of parts, railings, or panels onto the work surface, showing workers how to assemble panels and subcomponents. |

LTG Benefits

- Reduces design time by up to 70%, leading to a productivity increase of up to 25%.

- 100% validation to ensure that what is designed is what is built.

- Virtek has over 15,000 projectors currently in use in more than 600 manufacturing facilities.

- Virtually eliminates operator errors that result in rework.

- Ensures precision and quality with guided positioning of components for steel structures and beams.

- Eliminates the need to measure, square, and thread.

- Guided assembly allows new employees to be instantly productive by providing comprehensive training while building.

- Instantly identifies incorrectly cut or picked components.

You might also like