Virtek IRIS SPS

The Virtek Iris™ Spatial Positioning Systems (SPS) locates objects in 3D space and quickly adjusts to the assembly positions specified by CAD without the need for expensive tools or optical targets. The Iris system is compact and easy to use, improving productivity, quality, and safety in the workplace.

The Virtek IRIS SPS is a valuable tool for improving efficiency and accuracy in the manufacturing and assembly of large and complex parts.

Virtek Iris Spatial Positioning System

The Virtek IRIS SPS (Laser Positioning System) is a laser projection system designed to improve efficiency and accuracy in the manufacturing and assembly of large and complex parts, such as metal and composite structures.

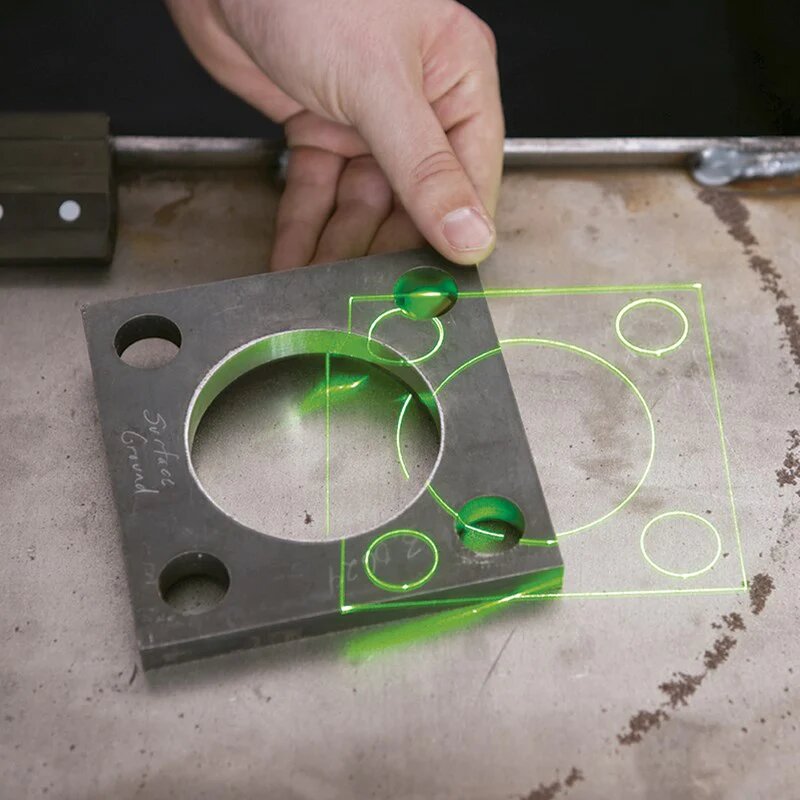

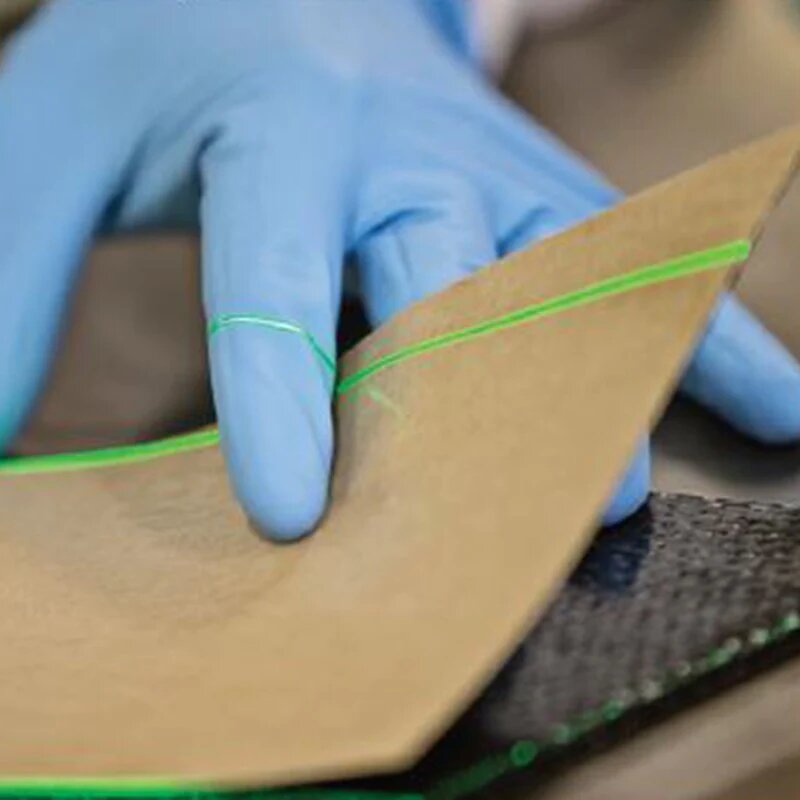

It uses high-precision laser technology to project patterns and templates onto three-dimensional surfaces with an accuracy of up to 0.05 mm, allowing precise verification and positioning of parts during assembly. The Virtek IRIS SPS control software is user-friendly and allows the import of CAD designs, facilitating the programming and control of projection patterns and templates.

The Virtek IRIS SPS (Laser Positioning System) is an advanced laser projection system designed to improve accuracy and efficiency in the manufacturing and assembly of large and complex parts, such as metal and composite structures.

IRIS SPS Features

Locates objects in 3D space and quickly fixes assembly positions specified by CAD, without the need for expensive tools or optical targets.

- Object scanning and digitization: The process begins with scanning and digitizing the object in 3D, using laser scanning technology to create a precise digital model of the object.

- Design and programming: Next, the digital model is used to create the system design and programming, allowing the projection of precise patterns and templates onto the object's surfaces during assembly.

- Assembly and setup: Once the design and programming have been created, the system is assembled and set up in the workplace, including the installation of laser projectors and position sensors.

- Verification and positioning: During assembly, the system projects precise patterns and templates onto the object's surfaces, allowing for the precise verification and positioning of parts during assembly. The system's position sensors detect the position of the parts in real-time and provide feedback to the control software.

- Integration with workflow: The system's control software is user-friendly and allows the import of CAD designs, facilitating the programming and control of projection patterns and templates. Additionally, the system can be easily integrated with the company's existing workflow.

- Accuracy and efficiency: The Virtek IRIS SPS uses high-precision laser technology to project patterns and templates onto three-dimensional surfaces with an accuracy of up to 0.05 mm, significantly improving accuracy and efficiency in the manufacturing and assembly of large and complex parts.

|

|

|

Eliminates manual measurement, marking, and adjustmentThe position of the part is taken directly from CAD data and projected with a laser onto it to achieve exact placement according to the design. |

Reduces templates and saves spaceReduces production costs and delays caused by using templates. |

Reduces human errors and applies design changes quicklyEliminates discrepancies between construction and design. Assemblers will always work with the most recent CAD file. |

In summary, the Virtek IRIS SPS is an advanced laser projection system that uses laser scanning technology and high-precision projection to improve efficiency and accuracy in the manufacturing and assembly of large and complex parts. The system easily integrates with the company's existing workflow and is easy to use and set up. With an accuracy of up to 0.05 mm, the Virtek IRIS SPS is a valuable tool for improving quality and efficiency in the manufacturing and assembly processes of large and complex parts.

Case Study: KomatsuVirtek IRIS Spatial Positioning System (IRIS SPS) is designed for manufacturers of high-engineering, low-volume products with extensive tooling. Komatsu America Corp eliminated assembly defects by 95% with IRIS SPS. |